How to Optimize Warehouse-to-Store Logistics in Metro Vancouver

Understanding the Metro Vancouver Landscape

Metro Vancouver is a bustling hub of activity, with a rapidly growing population and a diverse range of businesses. This region's unique geographical and logistical challenges make optimizing warehouse-to-store logistics crucial for any business hoping to thrive. The dense urban areas, combined with the sprawling suburban regions, require a strategic approach to ensure goods are delivered efficiently and cost-effectively.

One of the key elements to consider is the traffic congestion that frequently occurs in the area. Businesses must plan their delivery routes carefully to minimize delays and maximize efficiency. Additionally, understanding the specific needs and preferences of local consumers can help tailor logistics operations to better serve the market.

Leveraging Technology for Improved Efficiency

Incorporating technology into your logistics operations is essential for optimization. Advanced warehouse management systems can streamline inventory tracking, order processing, and route planning. By using real-time data analytics, businesses can make informed decisions and quickly adapt to changing circumstances.

For example, GPS tracking systems can provide up-to-the-minute information on delivery vehicle locations, allowing for dynamic route adjustments to avoid traffic congestion. Furthermore, utilizing automated systems for inventory management can significantly reduce human error and improve overall accuracy.

Implementing RFID Technology

Radio-frequency identification (RFID) technology is another powerful tool in optimizing warehouse-to-store logistics. By tagging products with RFID chips, businesses can track items throughout the supply chain with greater precision. This technology not only enhances inventory accuracy but also speeds up the picking and packing process, ensuring that products reach their destination faster.

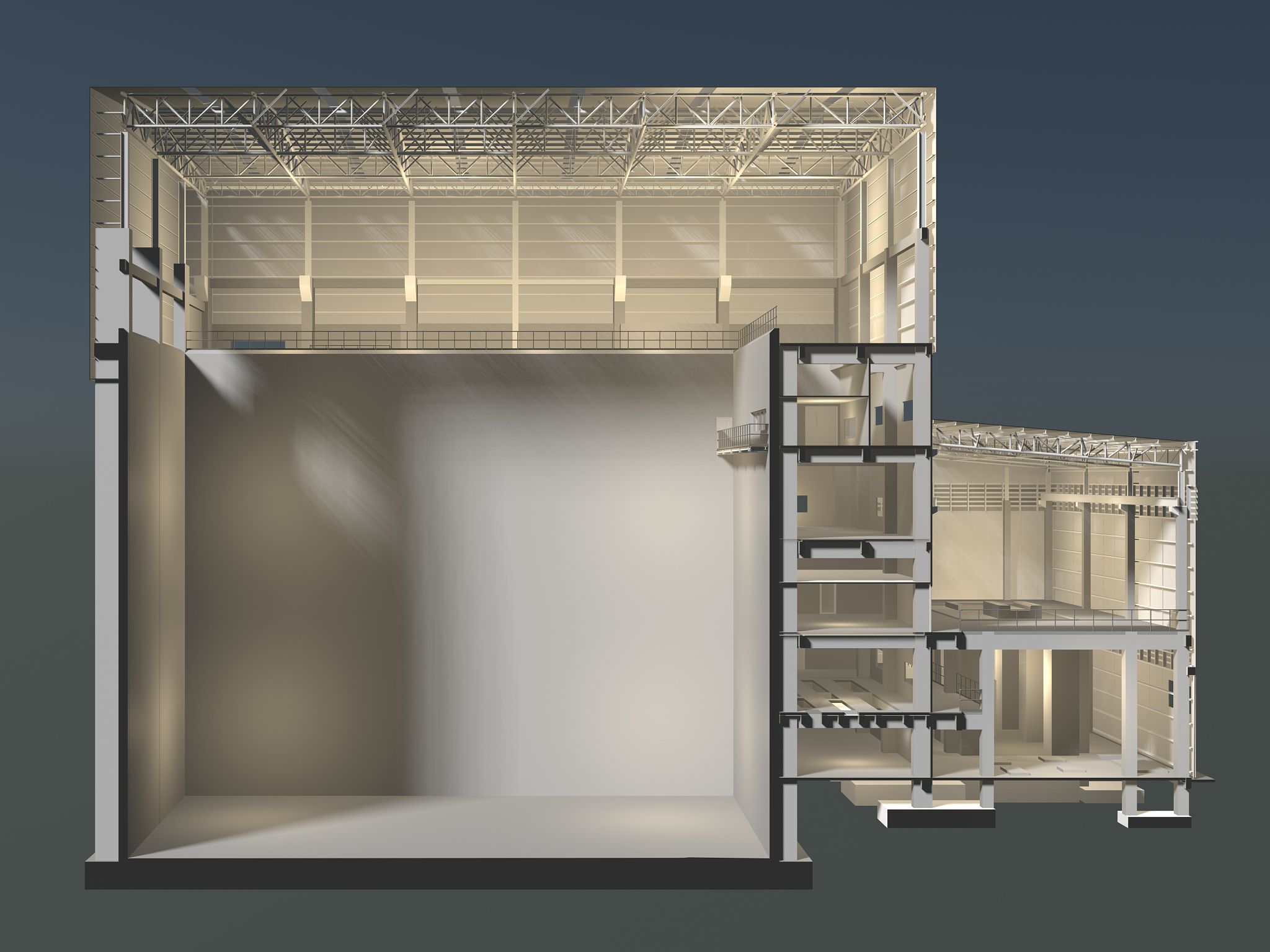

Optimizing Warehouse Layout and Operations

The physical setup of a warehouse plays a significant role in determining the efficiency of logistics operations. A well-organized warehouse layout can reduce the time spent retrieving and packing items, ultimately speeding up the entire supply chain process. Consider adopting a layout that supports efficient picking paths and minimizes unnecessary movement.

In addition to layout optimization, implementing standardized procedures for handling goods can significantly enhance operational efficiency. Training staff in efficient picking and packing techniques, as well as promoting a culture of continuous improvement, will contribute to smoother warehouse operations.

Maximizing Space Utilization

Effective space utilization is critical in densely populated areas like Metro Vancouver, where real estate can be costly. Consider vertical storage solutions and dynamic shelving systems to maximize available space. This approach not only increases storage capacity but also improves accessibility, allowing for quicker retrieval of items.

Collaborating with Local Partners

Building strong relationships with local partners can significantly enhance logistics operations. Collaborating with local carriers or third-party logistics providers who have in-depth knowledge of Metro Vancouver's infrastructure can improve delivery efficiency. These partners can offer valuable insights into optimal delivery times and routes that are less affected by traffic congestion.

Moreover, engaging with local businesses for shared warehousing or distribution facilities can lead to cost savings and improved service levels. By pooling resources, businesses can leverage economies of scale to reduce operational costs and enhance service speed.